Tokyo Factory

-

Address

4-3-15 Yotsugi, Katsushika-ku, Tokyo 124-0011, Japan

-

TEL

03-5671-1171

-

FAX

03-5671-1195

Line of Business

- Semiconductor and liquid crystal manufacturing equipment

- Machine Tool Parts

- Aircraft and vehicle seat parts

- Medical and nursing care equipment parts

- Packaging and food equipment parts, etc.

Main Clients

- EBARA CORPORATION

- Makino Milling Machine Co., Ltd.

- Jamco Corporation

- Yamato Jushi .Co., Ltd.

- DIC Corporation

- Other 110 companies

Features of the Factory

More than 70 years of experience in resin processing

-

-

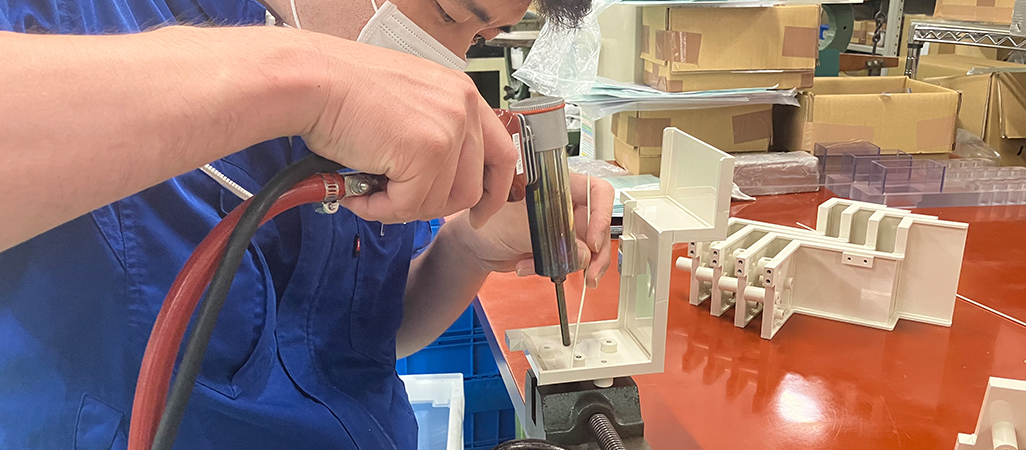

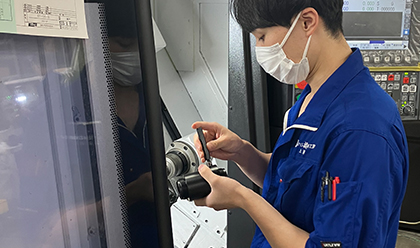

The Tokyo Factory specializes in cutting, plate processing, and vacuum/pressure forming processes for industrial plastic parts for medical equipment, industrial machinery, and air vehicles. Major products include seat tables for aircraft and bullet trains, CMP equipment parts for semiconductor manufacturing equipment (chemical mechanical polishing), and red lights for ambulances.

We have over 70 years of experience in resin processing, and our track record has led to many direct business relationships with major customers (Toyota Boshoku, Makino Milling Machine, DIC Corporation, Ebara Corporation, etc.).

Introduction of proprietary production control system

-

-

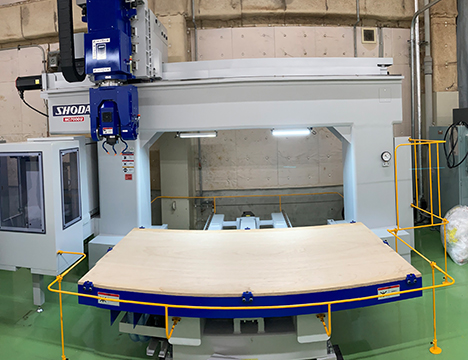

We have one of the largest vacuum and pressure molding machines (1000mm x 2000mm) in Tokyo, four 5-axis NC routers, eight machining centers, and eight NC lathes. The company has introduced its own production management system, which shares information from order receipt to production throughout the company to facilitate inventory control and shorten production lead times. In addition, as an IT initiative, we have built an in-house LAN for server management and cloud storage of customer drawing data, processing data, etc., for the peace of mind of our customers.

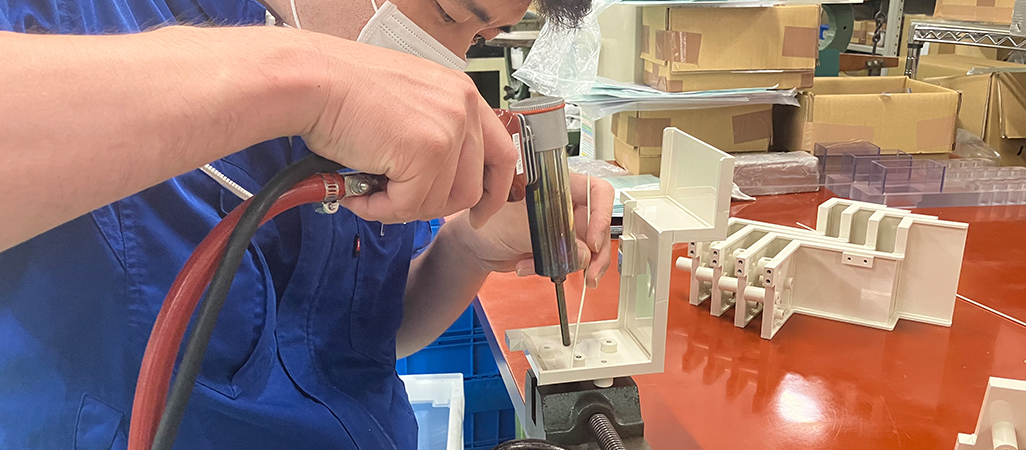

One-stop service from machining to assembly

-

-

The strength of our factory is that our cutting and machining departments work together with our molding and assembly departments to make full use of the most appropriate equipment and technology, enabling us to manufacture and assemble machined and molded products in-house in a one-stop shop. This enables us to supply high-quality products with short delivery times. We can also handle small to medium-sized lots (1 to 1,000 pieces).

In addition, we have a sales department that is well versed in the characteristics of resins and processing methods, and can propose the most appropriate processing method to meet the detailed requirements of our customers.

Main Facilities

-

Machining Centers

-

Machining Centers

-

Vacuum and Pressure Forming Machine

-

Vacuum Forming Machine

-

NC router

-

NC lathe

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Compact Precision CNC Lathe | CNC Lathe | Max. machining diameter Φ31, length 1000L | HASEGAWA MACHINE |

| Turning Center LB300-MY | CNC Lathe | Max. machining diameter Φ340 Length 400L | Okuma |

| CNC Lathe GENOS L250II | CNC Lathe | Max. machining diameter Φ200 Length 250L | Okuma |

| Used CNC lathe LB3000EX | CNC Lathe | Max. machining diameter Φ200 Length 400L | Okuma |

| Small precision CNC turret lathe (Hasegawa Machine) C42MY | CNC Lathe | Max. machining diameter Φ120 Length 150L | HASEGAWA MACHINE |

| CNC lathe LB3000EXII | CNC Lathe | Max. machining diameter Φ340 Length 450L | Okuma |

| Used NC router | NC router | Max. machining work size X1300 Y 2100 Z-595 (1300x2100) | SHODA |

| NC router for flat surface NC1001-3012 | NC router | Max. workpiece size X3700 Y-1300 Z-230 (Table 1200x3000) | SHODA |

| 5-axis control NC router PTM5000U-1216 | NC router | Max. workpiece size X1200 Y 1600 Z-490 (1000x1000) | SHODA |

| NC router for plastic processing (SHODA) NC7000U (2019 type) | NC router | Max. machining work size X 1600 Y 2660 Z-515 (1300x2100) | SHODA |

| High Precision Turning Center (Hasegawa Machine)H30M | NC lathe machine | Max. machining diameter Φ40 Length 1000L | HASEGAWA MACHINE |

| Hasegawa Machine Model HT30 | NC lathe machine | Max. machining diameter Φ31 Length 1000L | HASEGAWA MACHINE |

| FNC74 machining center | Machining center | Max. machining work size X740 Y450 Z450 | Makino Milling Machine |

| Makino V55 vertical machining center | Machining center | Max. work size X900 Y500 Z600 | Makino Milling Machine |

| Makino V55 vertical machining center | Machining center | Max. workpiece size X900 Y550 Z600 | Makino Milling Machine |

| Okuma vertical machining center | Machining center | Max. workpiece size X1000 Y500 Z600 | Okuma |

| FANUC ROBODRILL | Machining center | Max. workpiece size X500 Y400 Z330 | FANUC |

| W1000Xd1 16K21 ATC Daiichi Technos Co. | Machining center | Max. workpiece size X1000 Y500 Z480 | BROTHER INDUSTRIES |

| FANUC ROBODRILL α-D21MiA5 | Machining center | Max. workpiece size X700 Y400 Z330 (400x850) | FANUC |

| Used Vacuum Forming Machine Model BVF-710-PWB | Vacuum forming machine | Max. machining workpiece size X700Y1000T (7.5 to 390 lower heater) | Fu-se Vacuum Forming |

| Vacuum Forming Machine BVF-1010-PWB | Vacuum forming machine | Max. workpiece size X1000Y1000T (15 to 450 bottom heater) | Fu-se Vacuum Forming |

| Vacuum and Pressure Forming Machine CUPF-1115-PWB | Vacuum forming machine | Max. workpiece size X1100Y1500T460 (20 to bottom heater) | Fu-se Vacuum Forming |

| Used Vacuum Forming Machine | Vacuum forming machine | Max. workpiece size X1000Y1000T (15 to 450 bottom heater) | Fu-se Vacuum Forming |

| Used Vacuum Forming Machine | Vacuum forming machine | Max. workpiece size X700Y1080T380 (12 to bottom heater) | Fu-se Vacuum Forming |

| Vacuum and Pressure Forming Machine CUPF-1020-PWB | Vacuum forming machine | Max. workpiece size X1000Y2000T800 (20 to bottom heater) | Fu-se Vacuum Forming |