Head Office / Osaka Factory

-

Address

6-15-14 Kamikita, Hirano-ku, Osaka-shi, Osaka 547-0001, Japan

-

TEL

06-6791-7000

-

FAX

06-6792-2311

Line of Business

- Gas turbine and precision parts manufacturing

- Small hole electrical discharge machining

- Various welding processes

Main Clients

- GE (General Electric Company)

- Mitsubishi Heavy Industries, Ltd.

- Hitachi, Ltd.

- Toshiba Energy Systems & Solutions Corporation

- YANMAR POWER TECHNOLOGY CO., LTD.

- Kanadevia Corporation

- IHI Corporation

- Other 20 companies

Features of the Factory

Manufacturing a wide range of products with advanced processing technology

-

-

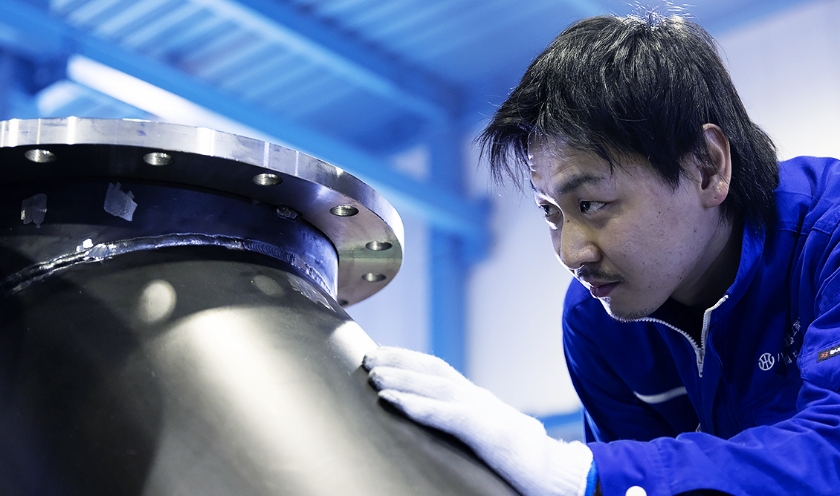

The Osaka Factory has a long track record and high technological capabilities, especially in the manufacture of combustor parts for gas turbines used in thermal power generation.

We are capable of complex and advanced welding of heat-resistant alloy materials such as HX, N263, HA282, HA188, and L605 using a variety of processing technologies including Tig welding, semi-automatic welding, machining, laser processing, and press work.

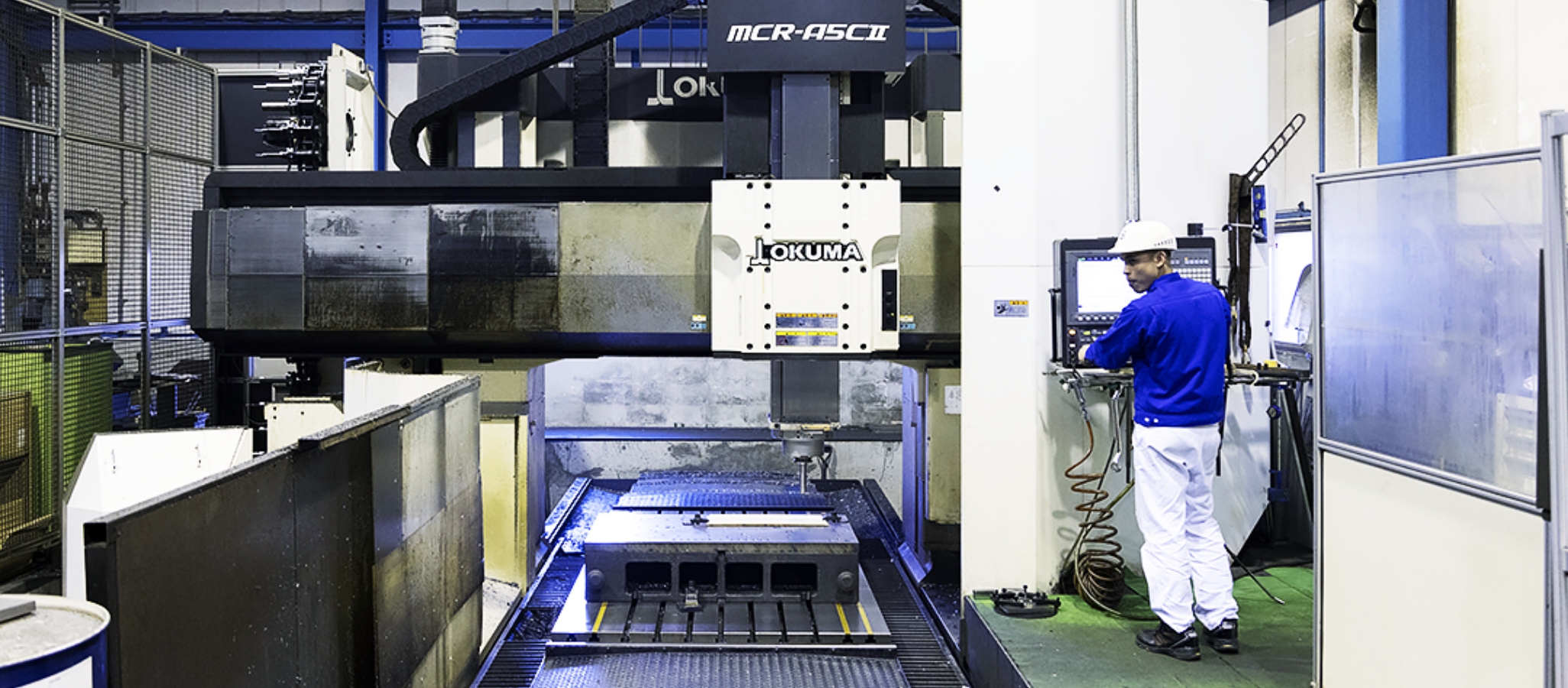

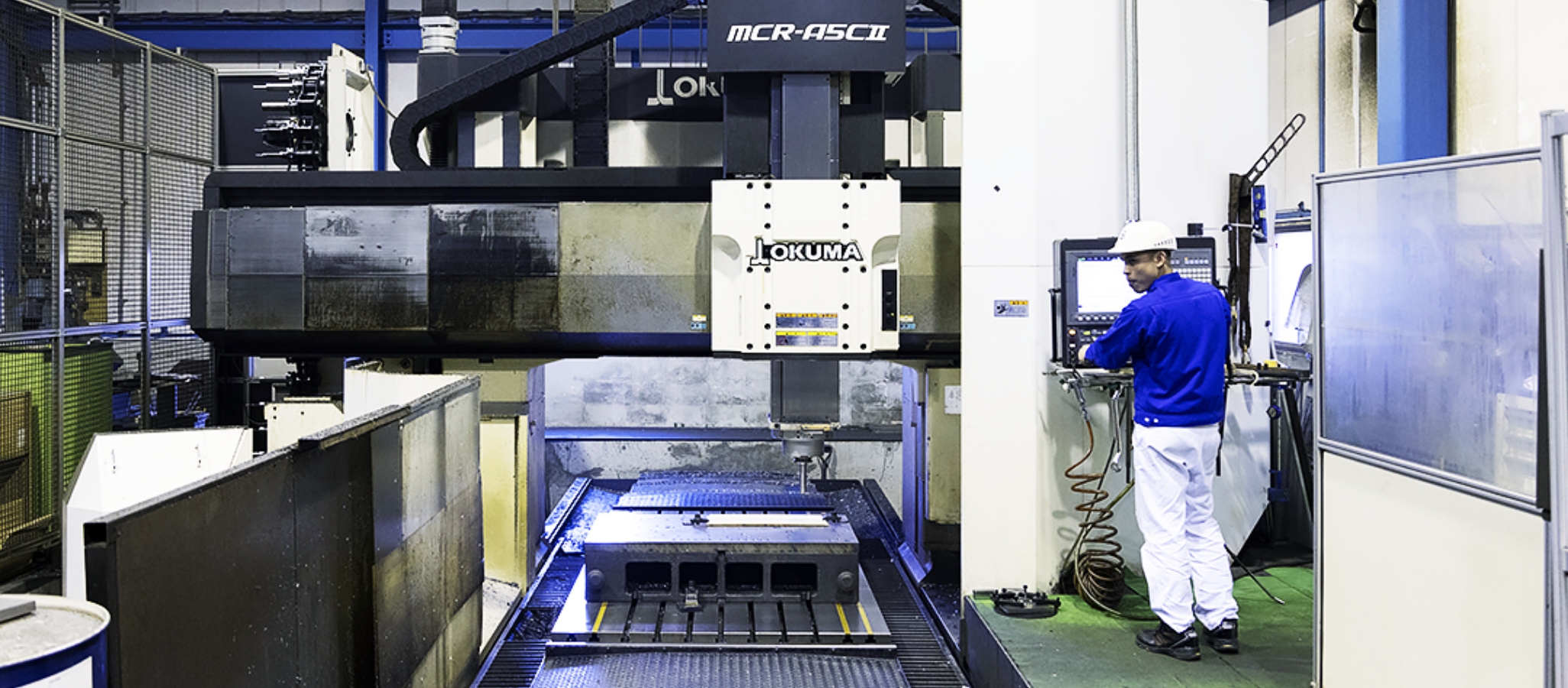

We also have a Tig robot welding machine, which requires advanced technology, and a double-column machining 5-face machine for precise machining, capable of handling sizes up to X3000 Y1300 Z1000. High-precision machining of ±0.05 mm is also possible. This enables us to meet diverse customer needs and manufacture a wide range of products.

Flexible response to customer needs

-

-

The ability to meet the diverse needs of customers is one of the strengths of the Osaka Factory. In the production of gas turbine parts, small-lot production from 1 piece to 100 pieces is possible. We can also handle a wide variety of fields such as wind power generation, fuel cells, ship parts, and agricultural machinery parts.

Our integrated production process from mold and jig design to manufacturing enables us to achieve customer satisfaction in terms of both quality and delivery time, and we are also able to respond promptly to express orders. We have built a close relationship with our customers by emphasizing direct transactions with major manufacturers without using trading companies, and have received orders from many major companies such as GE, Mitsubishi Heavy Industries, Doosan Enability, IHI, and others.

A culture of continuous awareness of issues

-

-

The Osaka Factory supplies parts of stable quality through RT inspection. In addition, the introduction of Tig welding robots has enabled us to automate the welding process by utilizing our long-standing welding know-how, thereby achieving improvements in both efficiency and quality.

In addition, to strengthen our production system, we have established a “culture of continuous problem awareness” and are constantly working on improvement activities. This has enabled us to increase production capacity and shorten delivery times, and has enabled us to respond quickly and flexibly to customer requests.

Main Facilities

-

Small Machining Center

-

Gantry Machining Center

-

3D Laser

-

Welding Robot

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| CAD/SOLIDWRKS Standard | 3D CAD | SOLIDWORKS | |

| CAD/SOLIDWRKS Standard | 3D CAD | SOLIDWORKS | |

| 3D 5-axis laser processing machine (Head office) | 3D Lasers | 2.5kw | Komatsu |

| Komatsu NTC laser cutting machine TLM-408DII33M (Head office) | 3D Lasers | 3.3kw | Komatsu |

| Wide-area CMM complete set | 3D Measuring Machine | 3D scanning, contact | Keyence |

| JBM Corporation Mastercam System (Head office) | CAD CAM | JBM | |

| JBM Corporation Mastercam System Hardware (Head office) | CAD CAM | JBM | |

| REVERSE-DNC-SYSTEM CAD (Head office) | CAM | REBIRTH | |

| Overhead crane (Head office) | cranes | t2.8 | NIPPON HOIST |

| Overhead crane (Head office) | cranes | t2.8 | NIPPON HOIST |

| Traveling crane (Head office) | cranes | 2.8t | NIPPON HOIST |

| Compressor molds (Head office) | Compressors | 37kw | KOBELCO |

| Strapac Semi-Automatic Packing Machine D-55 (Head Office) | Packing machine | ||

| DAIHEN Welding machine Welby WBP500L | semi-automatic welding machine | 500A | DAIHEN |

| YAMAKAWA Compact Triaxial Positioner (Head Office) | Positioner | 200kg | YAMAKAWA ENGINEERING |

| OKK VM7Ⅱ Vertical Mashiniga Center (Head office) | Machining center | OKK | |

| Okuma MCR-A5CII (Head office) | Machining center | Okuma | |

| NC fine hole electrical discharge machine CT900FX (Head office) | Fine hole EDM | ELENIX | |

| DAIHEN TIG welding robot A350P | Welding robot machine | 350A | DAIHEN |