Nara Factory

-

Address

374-7 Nukatabe-Minami-cho, Yamatokoriyama-shi, Nara 639-1035, Japan

-

TEL

0743-56-2811

-

FAX

0743-56-8445

Line of Business

- Precision Product Stamping

- Small gas turbine parts

- Various welding

- ASSY machining, etc.

Main Clients

- DAIWA SEIKO CO., LTD.

- YANMAR POWER TECHNOLOGY CO., LTD.

- SINFONIA TECHNOLOGY CO., LTD.

- TAKARA BELMONT CORPORATION.

- Other 20 companies

Features of the Factory

Technology to handle difficult materials

-

-

The Nara Factory manufactures mainly emergency gas turbine parts, agricultural machinery parts, and industrial engine parts (oil pans), and has a long history and expertise in the manufacture of emergency gas turbine parts in particular.

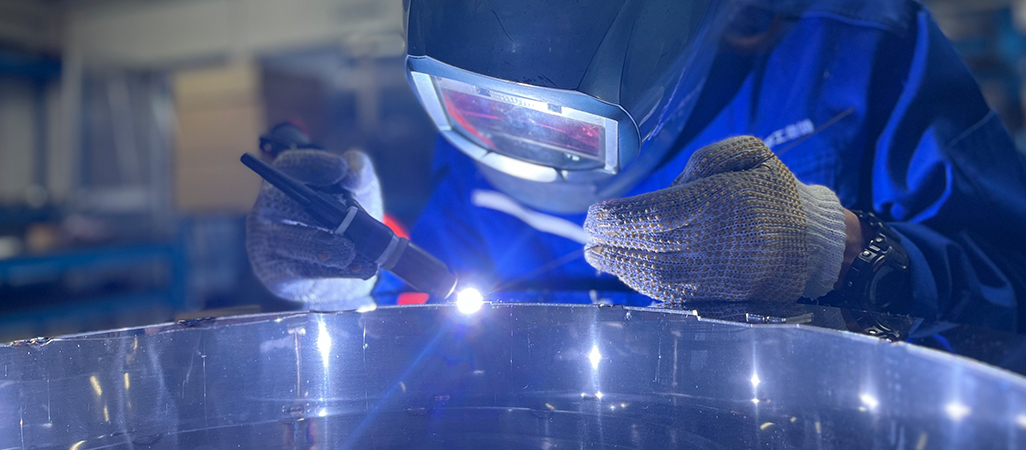

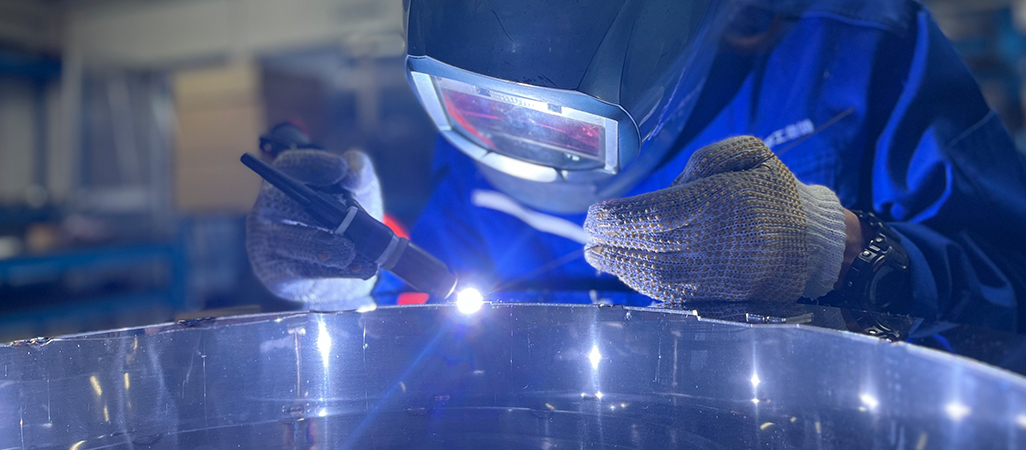

For difficult materials such as Inconel 601 (nickel alloy) and stainless steel, we use advanced technologies in laser processing, press working, semi-automatic welding, and TIG welding. For press work, we have a large 1,000-ton hydraulic press, and we can also handle deep drawing, which requires a great deal of skill.

Integrated System and Productivity Improvement Initiatives

-

-

We have established an “integrated production system” from material procurement to processing and completion, and are an ISO9001-certified factory, which has earned the trust of customers in a wide range of industries for its high level of quality and process control, and has a long track record of patronage. We can flexibly respond to various customer requests, such as small-lot production of a few units or express orders that are difficult for other companies to handle.

In addition, our constant implementation of JIT initiatives has eliminated traffic congestion at production facilities, saving space in the factory and reducing inventory. In parallel with this, we are promoting productivity improvement by “being aware of problems and repeating improvement activities,” which is one of our strengths.

Specialists who have mastered knowledge and technology are on staff

-

-

The manufacturing site is staffed with specialists and technicians who have mastered various types of processing expertise and techniques, and are still working daily to achieve even higher levels of performance. The management department also has specialists who have been trained in manufacturing, so they are well versed in production and can provide smooth consultation and transactions.

We have a large in-house base of human resources and equipment, which enables us to manufacture products without relying on outsourcing.

Main Facilities

-

3D Laser

-

Hydraulic 1000t press

-

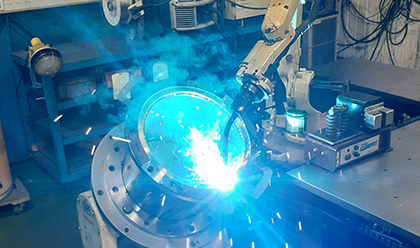

Welding Robot

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Three-dimensional laser machine TLM-608 | 3D Lasers | 1800 X 2400 | NIPPEI TOYAMA |

| TIG welding machine AVP-300 | TIG welding machine | 300A | DAIHEN |

| TIG welding machine AVP-300 | TIG welding machine | 300A | DAIHEN |

| TIG welding machine AVP-300 | TIG welding machine | 300A | DAIHEN |

| TIG welding machine AVP-300 | TIG welding machine | 300A | DAIHEN |

| S type spot welding machine S-6-355 | Spot welding machines | 35KVA | CHUO |

| Spot welding machine SLP-50A5 | Spot welding machines | 50KVA | TOA PRECISION MACHINERY |

| AC spot welding machine SL-AJ-601 | Spot welding machines | 50KVA | DAIHEN |

| Uncoiler UC3050 | Others | YUTANI | |

| Leveler B-600 | Others | YUTANI | |

| NC Fidder NC600-N | Others | YUTANI | |

| Submersible Leak Tester | Others | 400 X 700 | Amagasaki Plant, Hashida Giken Inc. |

| DYNA AUTO XD350Ⅱ | semi-automatic welding machine | 50-350A/15-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Digital Auto DM350 | semi-automatic welding machine | 30-350A/12-36V | DAIHEN |

| Hydraulic driven press brake FBD3512 | Brake press machine | 35t | AMADA |

| 150t press NCP150 | Press machine | 500 X 900 | NAGAO MACHINERY WORKS |

| 150t press MT-150 | Press machine | 540 X 900 | OKK |

| 80t press NCI-8-(2)-B | Press machine | 450 X 530 | AIDA |

| 400t press E2P-400-2 | Press machine | 1200 X 2300 | Komatsu |

| 220t press CF1-220C | Press machine | 550 X 800 | AIDA |

| 220t press CF1-22C | Press machine | 550 X 950 | AIDA |

| 200t press OBS200-3 | Press machine | 800 X 1200 | Komatsu |

| 400t press NSZ-4000W(2) | Press machine | 1200 X 2100 | AIDA |

| 1000t DP2-hydraulic press | Press machine | 1500 X 2500 | Kawasaki Hydromechanics Corp. |

| 400t press E2G400 | Press machine | 1200 X 2300 | Komatsu |

| Positioner A2PF301-JNN | Positioner | 300㎏ | DAIHEN |

| Welding robot ALMEGA AX-V6① | Welding robot machine | 3.14㎡ X 340° | DAIHEN |

| Welding robot ALMEGA AX-V6② | Welding robot machine | 3.14㎡ X 340° | DAIHEN |

| Welding robot ALMEGA AX-V6③ | Welding robot machine | 3.14㎡ X 340° | DAIHEN |

| Welding Robot Almega FD-B4 | Welding robot machine | 2.57㎡ X 340° | DAIHEN |

| Robot welding machine Almega FD-B6L | Welding robot machine | 6.37㎡ X 340° | DAIHEN |