Hita Factory

-

Address

1707-1 Ishimatsu-machi, Hita-shi, Oita 877-1352, Japan

-

TEL

0973-27-6200

-

FAX

0973-27-6555

Line of Business

- Manufacturing and sales of various springs

- Sales of spring related parts

- Etching processing, etc.

Main Clients

- OREC CO.,LTD.

- CANYCOM Co.

- Techno-Tsukihoshi Co.,Ltd.

- Other 160 companies

Characteristic processing technology

- Steel wire φ0.3 to 12.0 push springs, tension springs, and torsion springs

- Wire bending of steel wire φ0.5 to 12.0

- Bending process from blank spring material t0.1~2.0

- SUS304 flat wire, thickness 1.4~2.7mm, width 1.5~4.7mm push spring

- Adhesion and welding of resin parts

Main products

-

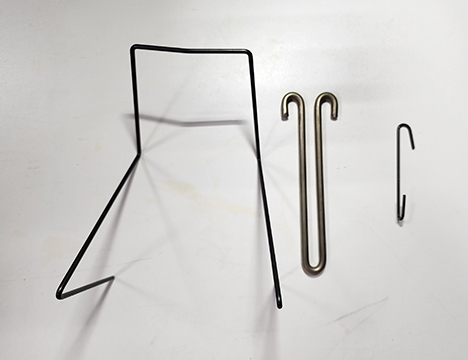

push spring

-

tension spring

-

leaf spring

-

wire bending

Features of the Factory

Custom-made production of various springs with our unique technology

-

-

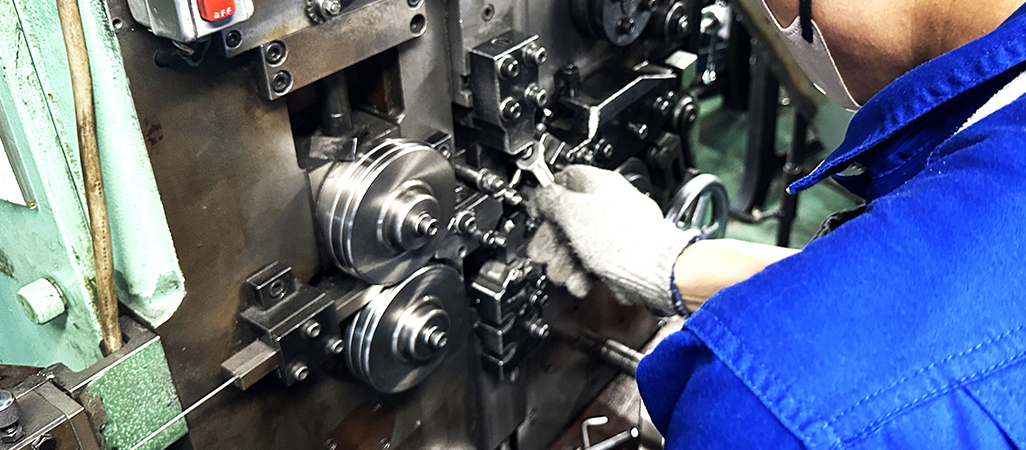

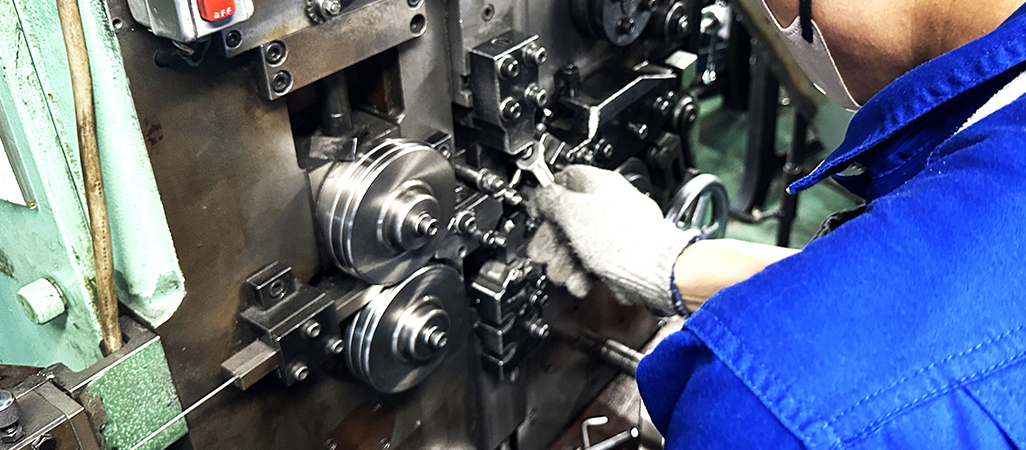

The Hita Factory manufactures various springs such as push springs, pull springs, twist springs, and plate springs made to order using our unique technology. We can handle wire diameters from φ0.5 to φ12, and carefully manufacture them by making full use of our wisdom and technology in each and every processing step. We can flexibly respond to prototyping and prototype changes.

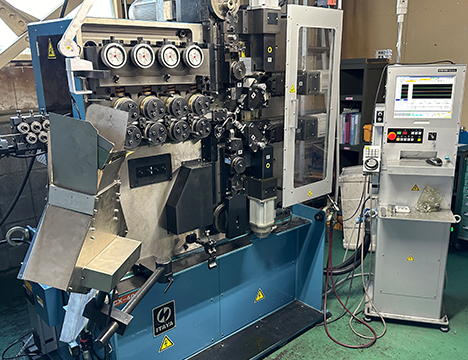

In 2024, we introduced the MX-40B forming machine (Itaya Manufacturing Co., Ltd.), which enables us to manufacture large-lot production and complex torsion springs. We also accept small-lot and multi-variety thin sheet spring production by laser processing. Laser processing machines are capable of processing plate thicknesses from 0.05 to 6.0.

Improving individual skills and passing on craftsmanship

-

-

We are working on “improving individual skills” and “passing on craftsmanship” in order to meet customer deadlines and quality. We are constantly striving to improve productivity and speed up the work process by leveling the workload and building a system that allows employees to handle various tasks.

We also strive for quality assurance through thorough process inspections (front-end process, own process) in each processing process.

Know-how and high technology accumulated over many years

-

-

The predecessor company of our factory was established in 1963, and has been doing business with customers throughout Kyushu for many years. Since its establishment, the company has been dealing with small-lot production of a wide variety of products, and the accumulated know-how and high level of technology have been passed down to the present day.

Springs are used in a wide variety of products, and our customers have a wide range of requests, but we place emphasis on “customer satisfaction” and strive for speedy response and quality improvement. We also manufacture the necessary processing jigs and dies in-house to reduce die costs.

Main Facilities

-

Forming Machine

-

Coiling Machine

-

My coiler

-

Press brake

-

Laser

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Compact laser cutting machine H17 | 2D Laser | 1000KW | AMADA |

| Mycoiler MYC-100 | NC spring winding machine | Wire diameter up to 16.0 | KS Giken |

| Mycoiler MYC-60 | NC spring winding machine | Wire diameter 1.2 to 6.0 | KS Giken |

| NC table bender (spring bending machine) | NC bender | Wire diameter 4.0 to 12.0 | Kyodo Engineering |

| Single head heading machine (air bender) | Air bender | Wire diameter 2.0 to 5.0 | Kyodo Engineering |

| Engineering (hydraulic bender) | Air bender | ||

| Twin head bending machine | Air bender | Wire diameter 2.0 to 5.0 | Kyodo Engineering |

| Automatic polishing machine (Nishikawa) | Grinding machines | Wire diameter 1.0 to 12.0 | Nishikawa Ironworks |

| Automatic polishing machine 1991 model SG-455-2 | Grinding machines | Wire diameter 0.8 to 2.5 | suicide industry |

| CSD-3 type machine | Coiling machines | Wire diameter 1.0 to 3.0 | SATO INSTRUMENTS |

| CSD-5 type machine | Coiling machines | Wire diameter 2.0 to 5.0 | SATO INSTRUMENTS |

| Coiling machine PCX-40A type | Coiling machines | Wire diameter 1.5 to 5.0 | SATO INSTRUMENTS |

| CSD-2 type machine | Coiling machines | Wire diameter 0.7 to 1.2 | SATO INSTRUMENTS |

| Kobelco Compressor | Compressors | Discharge pressure 0.83 MPa | Kobe Steel |

| Mechanical shearing | shearing machines | Thickness 0.3t to 6.0t | AMADA |

| Makita rebar cutter/MISUMI | Cutting machine | Up to 16.0 max. diameter | Makita |

| Fujitsu server PRIMERGY | Others | Fujitsu | |

| AP100SLPK (used) AMADA | Others | AMADA | |

| ARIES 224Ai | Turret punch press | 20t | AMADA |

| Electric furnace | Electric furnace | 24KW | Tokyo Gas Electric Furnace |

| Downward washer punching die D/A φ23.8 Amada | Half shear punch | Plate thickness 1.0 | AMADA |

| AB Washer punching die S/A | Half shear punch | Plate thickness 1.0 | AMADA |

| AB Washer die-cutting die S/A | Half shear punch | Plate thickness 1.0 | AMADA |

| AB Washer die-cutting die S/A | Half shear punch | Plate thickness 1.0 | AMADA |

| AUTOMATIC SPRING TESTER | Spring testing machine | onestec | |

| Deburring Machine | Deburring machine | 250W | TAKT |

| Cstα Guide Assy | Punch guide | AMADA | |

| Cstα Guide Assy | Punch guide | AMADA | |

| Cstα Guide Assy | Punch guide | AMADA | |

| Forming machine GX-40 | Forming machine | Wire diameter 1.8 to 3.5 | NUCOIL |

| Forming machine MX-40 | Forming machine | Wire diameter 1.5 to 4.0 | ITAYA ENGINEERING |

| Forming machine GX-40H24 | Forming machine | ||

| Ram type milling machine | Milling machine | Ram type | Matsuura Machinery |

| Amada FMB062 fine micron bender | Brake press machine | 6t press | AMADA |

| Punch press M-300 | Press machine | 3t press | China Machinery |

| Universal press SPH-30C | Press machine | 30t press | AMADA |

| Used Amada power press TP-25 1990 | Press machine | 35t press | AMADA |

| Centrifuge AT18 Kata PL-A Akimoto Seisakusho | Centrifuge | Akimoto Manufacturing | |

| Automatic polisher | Grinding machines | Wire diameter 1.0 to 12.0 | Nishikawa Ironworks |

| Dainichi 4m lathe DLG-SHB64×400 made in 1984 | Lathe machine | Max. diameter SS up to 16.0 | Dainichi |