Inazawa Factory

-

Address

133 Inokuchi-Oyabata-cho, Inazawa-shi, Aichi 492-8156, Japan

-

TEL

0587-21-1026

-

FAX

0587-23-2711

Line of Business

- Plastic / Resin processing

Main Clients

- YKK Corporation

- ADVANCE ELECTRIC CO., INC.

- Shibuya Corp.

- Other 150 companies

Features of the Factory

Outstanding technical capabilities in plastic cutting process chosen by major companies

-

-

The Inazawa Factory boasts outstanding technical capabilities in the field of plastic cutting and processing, combining the flexibility to produce a wide variety of products in small quantities from a single piece using a 3-axis machining center and various cutting machines, with the capacity for mass production of several hundred pieces.

Our high-precision machining that achieves a dimensional tolerance of ±0.05 mm is trusted in an industry with strict quality requirements. In particular, our special technology for transparent acrylic parts guarantees a surface roughness of Rz1.6 or less at all times for a fine finish, and is a clear differentiating factor in meeting the advanced needs of our customers. In addition, our buffing technology for acrylics has been adopted as a standard sample by major manufacturers.

Flexible support for small-quantity, high-mix production as well as mass production

-

-

The factory is equipped with 12 machining centers, 4 5-axis machining centers, 9 CNC lathes, and 5 multi-tasking lathes. Inspection equipment includes image dimension measuring machines and digital microscopes.

In order to accommodate both low-volume, high-mix production and short lead-time projects as well as mass production, we have established a two-shift day/night production system, with daytime production focused on projects requiring flexibility and nighttime production focused on mass production. In terms of delivery time, we can also handle projects with a short delivery time of less than one week.

Cooperating with other factories to meet customer needs

-

-

Although the work is divided among the three divisions of machining centers, lathes, and finishing, everyone in the division is a multi-skilled worker, and even younger employees are trained to be able to handle all tasks in the division they are in charge of. Since plastic cutting has characteristics that differ from both metal parts and injection-molded products, we strive to meet customer needs, including making technical proposals.

In addition, our partner factories handle processes that are closely related to plastic cutting, including rubber processing, thermosetting resin processing, 3D printers, resin casting processing, and injection molding processing.

Main Facilities

-

smart

-

C-600_1

-

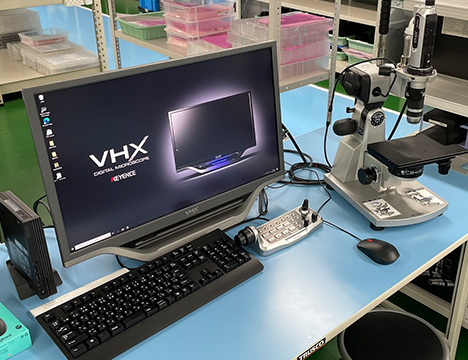

VHX

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Yamazaki Mazak VARIAXIS C-600 | 5-axis machining center | Φ600×500×Z500 | Mazak |

| Yamazaki Mazak VARIAXIS C-600 | 5-axis machining center | Φ600×500×Z500 | Mazak |

| NMV5000DCG・MORI SEIKI | 5-axis machining center | 730×510×510 | MORI SEIKI |

| DMU50ecoline・DMG | 5-axis machining center | 500×450×400 | DMG |

| Yamazaki Mazak CNC Lathe QT250 500U 2 units | CNC Lathe | 10" (φ75) | Mazak |

| QTS-150S・Mazak | CNC Lathe | 8" (φ45) | Mazak |

| TAC510・Takizawa Ironworks | CNC Lathe | 10" (φ80-L500) | Takizawa Ironworks |

| NEXUS150・Mazak | CNC Lathe | 8" (φ45) | Mazak |

| SQT-250・Mazak | CNC Lathe | 10" (φ65) | Mazak |

| QTS-250・Mazak | CNC Lathe | 10" (φ80) | Mazak |

| QTS-200・Mazak | CNC Lathe | 10" (φ60) | Mazak |

| QTP-50S・Mazak | CNC Lathe | 5" (φ30) | Mazak |

| QTP-50S・Mazak | CNC Lathe | 5" (φ30) | Mazak |

| Yamazaki Mazak QUICK TURN250 500U | CNC Lathe | 10" (φ75) | Mazak |

| Grinding machine | Grinding machines | BT40 | YAMATO KIKOU |

| Compressor ZV22AX | Compressors | 30 hp | MITSUI SEIKI |

| ZV-22・Mitsui Seiki | Compressors | 30 hp | MITSUI SEIKI |

| OSP-22VAN2・Hitachi Seiki | Compressors | 30 hp | Hitachi Seiki |

| Bench-top turret lathe | Lathe machine | 0.75kw | TUKASA |

| Turret lathe | Lathe machine | 0.75kw | TUKASA |

| Turret lathe | Lathe machine | 0.75kw | TUKASA |

| HP-1・SHINX | Others | 1300×1300×50 | SHINX |

| NAVELOCK TIGHT 5-Axis Machine Vises | Others | Width 75 | NABEYA |

| NR-2100-D・Nakao Iron Works | Others | 2000×1500×100 | Nakao Iron Works |

| HA-400 - Amada | Band saw (cutting machine) | 400 x 400 (maximum surface area) | AMADA |

| Laxo contour | Band saw (cutting machine) | 200×200 | TOKYO SHINDENKI |

| Victor Milling Chuck | Milling machine | 10" | Kobayashi Iron Works |

| SNC-CV2 KASUGA Factory | Milling machine | 730×300×400 | KASUGA Factory |

| SV-500 Mori Seiki | Machining center | 800×510×500 | MORI SEIKI |

| V-414/32・Mazak | Machining center | 813×410×460 | Mazak |

| VTC-200B・Mazak | Machining center | 1120×510×510 | Mazak |

| ACCUMILL4000・MORI SEIKI | Machining center | 560×450×400 | MORI SEIKI |

| α-T14iE FANUC | Machining center | 635×510×460 | FANUC |

| DMC-635V ecoline・DMG MORI | Machining center | 500×400×330 | DMG MORI |

| MB-66VA Okuma | Machining center | 1500×660×660 | Okuma |

| ROBODRILL α-D14MiB5Plus | Machining center | 635×510×460 | FANUC |

| NVX5100II・MORI SEIKI (purchase of leased assets) | Machining center | 1050×530×510 | MORI SEIKI |

| α-T14iE FANUC | Machining center | 635×510×460 | FANUC |

| α-T14iE FANUC | Machining center | 635×510×460 | FANUC |

| α-T14iE FANUC | Machining center | 635×510×460 | FANUC |

| Foot-operated hydraulic hand lifter | Lift | 500㎏ | TRUSCO |

| Dryer Matsui | Dryer | 0-200° | MATSUI |

| Digital microscope VHX-H6M | Inspection machines | - | KEYENCE |

| Mazak NC multi-tasking lathe 200SY 2001 (Used) | Combined lathe | 8" (φ45) | Mazak |

| INTEGREX 200-Ⅳ・Mazak | Combined lathe | 8" (φ65) | Mazak |

| NEXUS250MY・Mazak | Combined lathe | 10" (φ75) | Mazak |

| NEXUS250-ⅡM・Mazak | Combined lathe | 10" (φ75) | Mazak |

| INTEGREX j-200・Mazak | Combined lathe | 8" (φ45) | Mazak |