Yao Factory

-

Address

6-218 Ota-shinmachi, Yao-shi, Osaka 581-0039, Japan

-

TEL

072-948-8600

-

FAX

072-948-4600

Line of Business

- Precision Sheet Metal

- Chassis Fabrication

Main Clients

- YUYAMA MFG. CO., LTD.

- TERASAKI ELECTRIC CO.,LTD.

- Nisshin Tokki Co.

- OKAMURA CORPORATION.

- Japan Cash Machine Co., Ltd.

- Other 20 companies

Features of the Factory

Strength in thin plate processing and fabrication

-

-

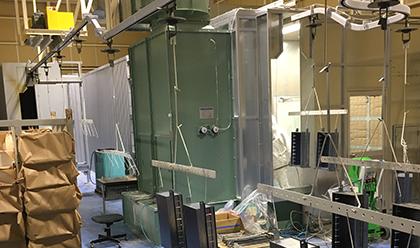

The Yao Factory is equipped with painting facilities and is capable of integrated production from flat sheets to finished products, including punching and bending, welding, painting, and assembly.

We are especially good at processing thin sheets, and we process many exterior parts that are visible to the human eye. Our main products include medicine storage cabinets and safes used in dispensing pharmacies, equipment used by pharmacists, and medical record storage cabinets. We also mainly perform sheet metal work and painting, but we can also assemble machines from parts supplied by customers.

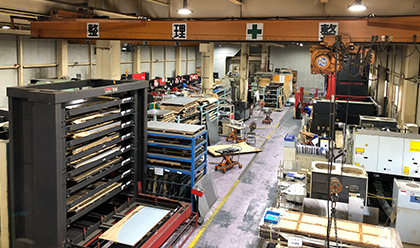

Large 2,000 m2, 2-story factory

-

-

Our factory is conveniently located in Yao City, Osaka Prefecture, making it easy for customers to visit us. We frequently collaborate with other factories of Hashida Giken. The factory site is very spacious, with a 2,000 m2 two-story building, and is capable of assembling large products.

As a sheet metal factory, we receive a variety of requests, such as prototype production, quick delivery, high-mix, small-lot production, and so on. In order to meet these requirements, we have introduced a production control system to manage progress and share information between processes, while thoroughly reducing setup time.

We have also introduced TECHS, a DX for the manufacturing industry, for order management.

Passing on know-how cultivated over many years to the next generation

-

-

The factory has long been involved in the manufacture of steel furniture, mainly thin plates, and has expertise in steel furniture design and knowledge of welding methods for exterior parts that it has cultivated through its long history. Many of our experienced factory staff members are elderly, and at best, they are highly skilled. At worst, however, we are concerned about maintaining our system in the future, so we are working on the urgent task of passing on our skills to the next generation.

We are taking on any challenge with the philosophy of responding to our customers' problems as much as possible, without being bound by conventional frameworks.

Main Facilities

-

laser

-

brake

-

EM-2

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Amada 2D carbon dioxide laser processing machine | 2D Laser | 4kw 3070×1550 | AMADA |

| Komatsu 2D carbon dioxide laser processing machine | 2D Laser | 4kw 2500×1250 | Komatsu |

| Tig welding machine (Panasonic YC-300WS4) | TIG welding machine | 26kVA | Panasonic |

| Spot welding machine | Spot welding machines | Chuo Seisakusho | |

| Spot welding machine | Spot welding machines | Chuo Seisakusho | |

| Production control system | Others | Technoa | |

| CADMAC lock license (Yao) | Others | CADMAC | |

| Iwata Compressor | Others | Iwata | |

| Overhead traveling crane | Others | ||

| Set press | Others | AMADA | |

| Tapping machine used AMADA CO., LTD. | Others | AMADA | |

| Air Support AMADA CO., LTD. | Others | AMADA | |

| NEW Electro Shiner S Conic Co. | Others | JESCO | |

| NCT Mold Polishing Machine | Others | AMADA | |

| Deburring system Flutter | Others | Authentec | |

| Flight hole bearing | Others | Ashina Ironworks | |

| Rear mounted manibrator AMADA CO., LTD. | Others | AMADA | |

| CNC turret punch press AMADA CO., LTD. | Turret punch press | 30t | AMADA |

| Pre-treatment cleaning equipment | Coating related | NISSEI ENGINEERING | |

| Air blow deck | Coating related | NISSEI ENGINEERING | |

| Steam boiler equipment | Coating related | NISSEI ENGINEERING | |

| Dustproof panel | Coating related | NISSEI ENGINEERING | |

| Daichen CO2/MAG welding machine (Inazawa) | semi-automatic welding machine | 18kVA | DAIHEN |

| Welding machine YD350RE2TAC | semi-automatic welding machine | 17kVA | Panasonic |

| Semi-automatic machine YM350GBI | semi-automatic welding machine | 16.4kVA | Panasonic |

| YE-200BL2 | semi-automatic welding machine | 7.3kVA | Panasonic |

| YE-200BL2 | semi-automatic welding machine | 7.3kVA | Panasonic |

| Welding machine YD-350VR1 | semi-automatic welding machine | 16.4kVA | Panasonic |

| Press Brakes | Brake press machine | 3030×120 | KANSAITEKKO |

| Hydraulic Brake Press | Brake press machine | 80t 2500mm | AMADA |

| Fine Alpha Brake Amada Co. | Brake press machine | 80t 2000㎜ | AMADA |

| Brake Press | Brake press machine | 35t 1000㎜ | Komatsu |

| Support Drive Press Brake | Brake press machine | 50t 2000㎜ | Komatsu |

| Press Brake | Brake press machine | 35t 1000㎜ | Komatsu |

| Fine Alpha Amada Co. | Brake press machine | 80t 2500㎜ | AMADA |

| Amada Press Brake | Brake press machine | 130t 3000㎜ | AMADA |

| OBW200 & Multi-axis Robot | Press machine | 200t | Komatsu |

| Power Press | Press machine | 150t | NAGAO |

| Stud welding machine | Welding machines | AMADA | |

| Multi-spot welding machine modification | Welding machines | Chuo Seisakusho | |

| Nut Feeder | Welding machines | Panasonic |