Kaizuka Factory

-

Address

749-1 Oji, Kaizuka-shi, Osaka 597-0051, Japan

-

TEL

072-437-8618

-

FAX

072-437-8658

Line of Business

- Rubber molding die fabrication

- Industrial heating furnace parts, etc.

Main Clients

- KOYO THERMO SYSTEMS CO., LTD.

- Sumitomo Rubber Industries, Ltd.

- Tozetsu Kogyo Ltd.

- Other 5 companies

Features of the Factory

A wide variety of processing technologies

-

-

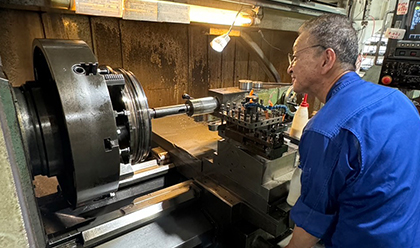

The Kaizuka Factory manufactures industrial heat treatment furnace transfer parts and other parts in an integrated manner, from machining to welding.

We specialize in single-part machining using NC lathes (for high-precision Φ5 to Φ400), general-purpose lathes, machining centers, and welding, and can also handle semi-automatic welding and Tig welding (iron, stainless steel, special steel, etc.) We can also manufacture can products from primary processing to welding to final machining and finishing, as well as shape processing using CAD/CAM and mold manufacturing. We can also provide CAD/CAM-based shape processing and die fabrication services.

We can also process various metals such as stainless steel, aluminum, copper, brass, and titanium.

Strengths in high-mix, small-lot, quick delivery

-

-

We specialize in small lots (1 piece to 50 pieces) of various types of machine parts, molds, and can products. We are also strong in our ability to provide high quality products with short delivery times, and have a proven track record of providing same-day service for urgent repair parts.

In addition, with the cooperation of suppliers with whom we have built a close relationship of trust, we can also handle wire processing, plating, quenching, and cutting of mass-produced parts on an outsourced basis.

In the spirit of “try first”

-

-

With regard to productivity, all employees are constantly aware of the problems and strive to improve safety, quality, and speed by constantly incorporating information on cutting tools and machining jigs, which are constantly evolving.

Even with difficult products or products that have been rejected by other companies, we keep in mind the spirit of “try first” and strive to complete products by any means possible. Although the staff at the Kaizuka Factory is relatively young in age, we aim to create an organization that makes people think, “If you have a problem, turn to Hashida Giken.

Main Facilities

-

BL4000

-

NK40

-

BL3000

-

NV4000

Facilities List

※Swipe on the table to scroll.

| Name | Type | Capability | Maker |

|---|---|---|---|

| Okuma lathe turning machine LB4000EXII (Kaizuka) | NC lathe machine | φ400*700L | OKUMA |

| Okuma LB3000EXII Daiichi Technos Co. | NC lathe machine | φ350*450L | OKUMA |

| Dainichi NC Lathe M63 | NC lathe machine | φ500*2500L | Dainichi |

| Osumi NC Spinning Plate LB25 Used (Kaizuka) | NC lathe machine | φ250*600L | OKUMA |

| Dainichi NC Plate M75 Used (Kaizuka) | NC lathe machine | φ650*1500L | Dainichi |

| Used NC Lathe LR-25, made in 1992 | NC lathe machine | φ250*600L | OKUMA |

| Hitachi NC lathe NK40-S used (Kaizuka) | NC lathe machine | φ350*1500L | Hitachi Seiki |

| 300P | TIG welding machine | 300A | DAIHEN |

| YC-300BP2 | TIG welding machine | 300A | Panasonic |

| Shin Nippon Koki radial drilling machine used (Kaizuka) | Drilling machine | 1200㎜ | SHIN NIPPON KOKI |

| Yamazaki Machining 1500 x 550 used (Kaizuka) | Machining center | 1500*550*500L | MAZAK |

| Mori Factory 40 Standing Massive NV5000a1B Used (Kaizuka) | Machining center | 1000*600*350L | DMG MORI |

| Mori Factory Standing Massive Center NV5000 Used (Kaizuka) | Machining center | 750*600*500L | DMG MORI |

| Yamazaki Machining FJV60/120 (Kaizuka) | Machining center | 3000*1400*550L | MAZAK |

| Yamazaki Machining Center FJV-35/60 (Kaizuka) | Machining center | 1450*860*600L | MAZAK |

| YD-350GB2 | semi-automatic welding machine | 350A | Panasonic |

| YD-400GT3 | semi-automatic welding machine | 400A | Panasonic |